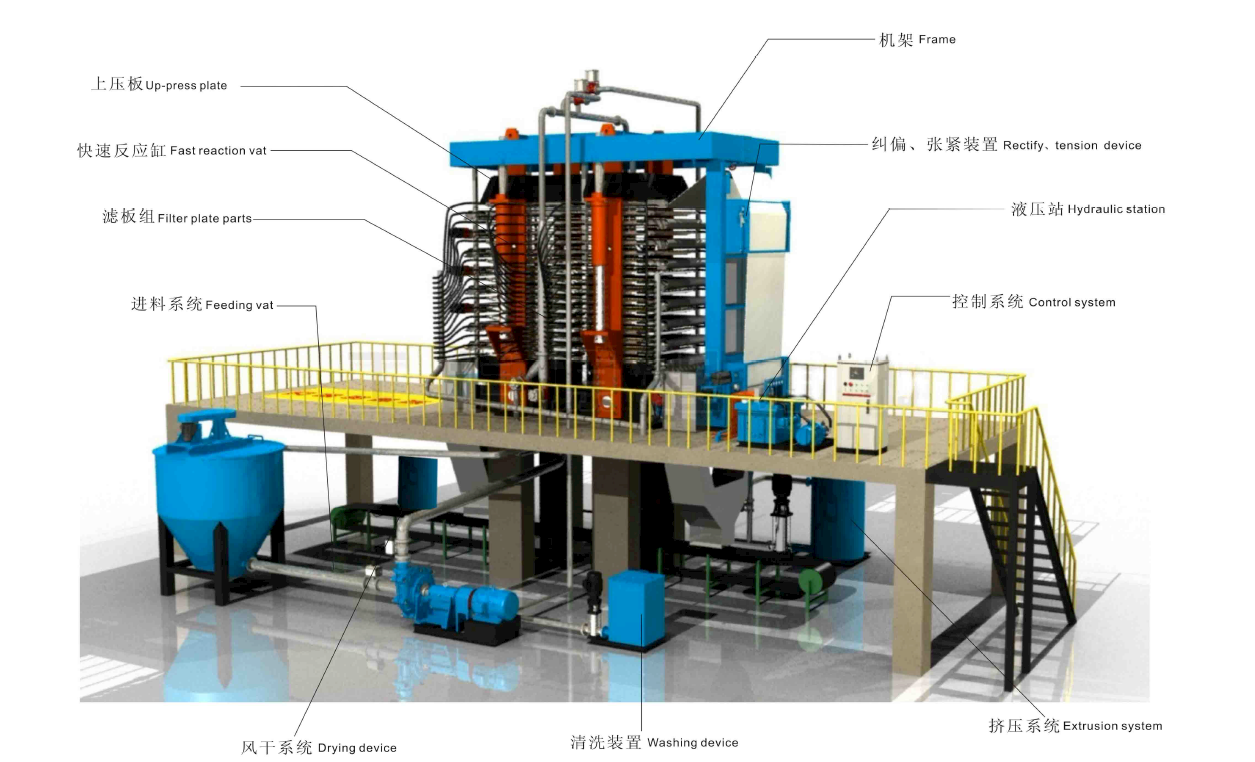

Equipment Description

The HVPF Vertical Automatic Press Filter manufactured by Nuclear Industry Yantai Tongxing is a new type of environment-friendly solid-liquid separation equipment with high working effectiveness and energy-saving. This product is able to filter the feeding slurry rapidly by utilizing pump pressure, gravity of the slurry and the compression between the rubber diaphragms, thus to achieve effective separation. The vertical automatic filter press has been widely adopted in the area of metallurgy, mining, chemical industry, coal, titanium dioxide, paper, food, pharmacy and environment protection. It is an updating technology of conventional filter press products and has following advantages.

- The filter plate adopts tower structure, horizontal filtering, compact design

- Continuous automatic filtering process

- Especially effective for the filtration of sticky material or low cake moisture demand situations

- Hydraulic control ensures the operation stability and safety

- Low cake water content, high treatment capacity and efficiency

Working Process

- Filtrating Phase: after closing filter plates, material slurry will be pumped into filter chamber. Filtered water pass through cloth and caked formed on the surface of the cloth.

- First extrusion: high pressure water enters into upper chamber to squeeze filtering cake.

- Washing (optional): washing solution is pumped into filter chamber passing though cake and clothe and discharged

- Second extrusion: similar to first extrusion

- Air drying: compressed air passes though cake to reduce the water content

- Filter cake discharge: filter plate will be opened after air drying and the filter cloth will rotate to let the filter cake dropping down. Meanwhile, filter cloth will enter into washing device for regeneration.

Equipment Structure