Equipment Description

After series process of compression, pressure and temperature increasing, the secondary evaporator steam generated in Mechanical Vapor Recompression (MVR) evaporator can be reused as heating steam. This technology can maintain the feed liquid in boiling status while the heating steam condensed into water, thus the steam which is supposed to be abandoned is fully utilized. Advantages of MVR evaporator include the recovery of latent heat, higher operational efficiency, reduced demands of external heating and cooling resources and less pollution. This product has been widely used in the production of milk, glucose, organic acid, VC, xylose and areas of pharmaceutical, chemical, biology, environmental engineering, wastewater treatment and paper making, especially for the materials of low boiling point or easy to evaporate.

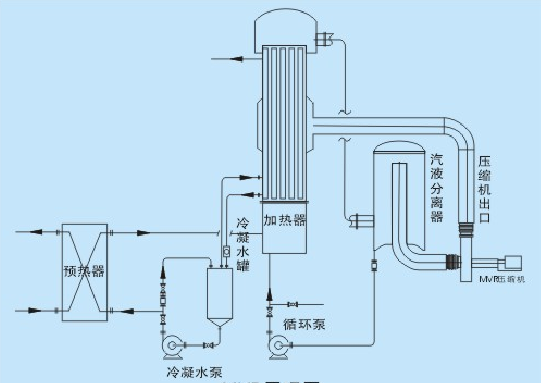

Equipment Components

Heater, separator, compressor, vacuum pumps, circulation pumps, operation platform, electric control cabinet, control valves and piping system

Equipment Features

- Requires only a extremely small amount of heating steam for startup purpose, no extra steam needed for normal operation condition, greatly reduce operation cost

- Using compressors to provide heat which can achieve moderate evaporation to improve product quality and reduce fouling

- No condenser required (or condensers with small surface area), simple structure, fully automatic

- Low temperature evaporation, no foam generated

- Equipped with CIP cleaning device