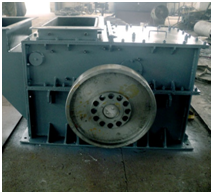

Crusher

Crushers are designed to physically reduce the size of objects so that they can be more suitable for disposing, recycling or further applications . The crushers produced by us include five different models which can process the size of raw materials from 200 to 350mm and generate discharges that have size less than 30mm . By selecting different motor power, the productivity of our crusher varies from 30 to 800 tons per hour.

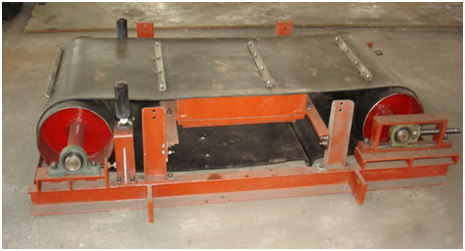

Magnetic Separator

Magnetic separator is a device aims to magnetically separate ferrous materials from non-magnetic materials. The ferrous materials are usually considered as impurities and thus their extraction can improve the product quality and reduce the potential of damaging sensitive machinery. In addition, the separation techniques are also used in metal recycling for economic purpose. The drum type magnetic separator we produce is suitable for belt width of 500, 650, 800, 1000 and 1200mm and is located at the end of the conveyor where bulk product gravitates off and the ferrous materials are carried further then discharged.

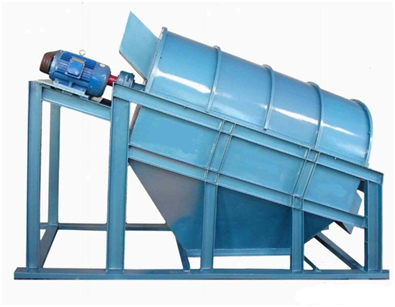

Drum Screen

GTS I drum screens manufactured by us are the most commonly used screening equipment. The screen inside will rotate continuously and hence the materials will move from the top to the bottom. In this way, the oversized materials will be retained in the screen and transported to the discharge chute for the next process, while the rest will pass through the screen and be collected in the bottom of the equipment. The cost of drum screens is relatively low due to their simple structures and convenient maintenance. GTS II drum screen is an upgrade version of GTS I, hence it employs the same principle and inherits the advantages of GTS I. The difference between them is that the GTS II uses an additional plate-type cleaning device which can constantly clean the screen thus to avoid the sieves from blocking.

Ration Coal Feeder

The ration coal feeder produced by our company is well structured; its reducer and motors are all in accordance with Schenck’s technical requirements. The coal feeder is small in size and hence it can be easily installed and maintained. The weighing device of the coal feeder adopts a unique double-roller structure designed by our company which can improve the deadweight capacity of the transducer and avoid measuring accuracy influenced by tension and deviation of the belt. In addition, a high-precision displacement detector is installed on the return belt to eliminate the measuring error from the changing of belt speed. For safety concerns, password is required for all the important operations and alarms are also equipped in case of unexpected events such as material blocking, material shortage or overweighing.

Vibrating Feeder

GZG series vibrating feeder is widely adopted in metallurgy, mining, chemical industrial, light industrial and construction materials. The vibrating feeder utilizes the synchronous vibration of the motor to uniformly handle lump, granular and powdery material in a continuous way. The feed rate can be changed conveniently by adjusting the excitation force. In addition, the structure of the feeder sealed which reduces dust pollution.