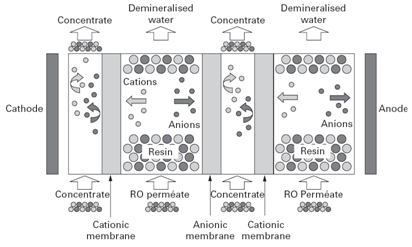

Traditional approaches use membrane separation and ion exchange to generate high purity water. EDI system is a state-of-art water treatment process which combines the semi-impermeable membrane technology and the ion-exchange media to provide high quality of demineralized water with high efficiency. This technology differs from other water purification processes as it is done without using any chemical treatments. With EDI’s membranes and electricity, million gallons of acid and caustic chemicals that the old processes required are replaced daily. The EDI system produced by JunYue has been widely applied to many fields with great success; therefore, we JunYue are able to provide you the best solution to your specific requirements.

Applications

JunYue’s EDI system is suitable to be applied in the following fields:

- Power/Utilities

- Biotechnology/Pharmaceutical

- Semiconductor/Electronics

- Surface Finishing (e.g. Automotive)

- Cosmetic

- General Industry

Working Process

An EDI cell consists of a series deionization chamber. Each chamber contains an ion exchange resin that packed between a cationic exchange membrane and an anionic exchange membrane. Only the ions can pass through the membrane, while water is retained. As the water enters the cell, the strong ions are captured out of the water by the mixed bed resin. When a voltage is applied across the cell, charged ions begin to migrate across the resin and towards to the respective, oppositely-charged electrodes. In this way, these ions are continuously removed and pass through the membranes into the adjacent concentrate compartments. Since the strong ions are removed from the water stream, the conductivity of the stream becomes relatively low. At this point, the applied electrical potential will splits water at the surface of the resin beads, producing hydrogen and hydroxyl ions which continuously regenerate the resin

Advantages

Compared with traditional ion exchange treatment technology, JunYue’s EDI system has following advantages:

- Simple structure and continuous operation

- Eliminate chemical for resin regeneration, environmental sustainability

- Safe and reliable

- Low power consumption

- Small floor space

- Automatic control

- Produce extremely pure water in a constant flow

EDI feed water requirements

Generally, the EDI feed water comes from the permeate water of second stage RO process with conductivity between 1 to 20 uS/cm. Other parameters’ requirements are stated in the following table

pH value | 5 ~ 8 |

Temperature | 5 degree C ~ 35 degree C |

Inlet Pressure | 0.15 ~ 0.5 Mpa |

Hardness (CaCO3) | Max. 1.o ppm |

TOC | Max. 0.5 ppm |

Silica | Max. 0.5 ppm |

Total CO2 | Less than 5 ppm |