Features & Advantages

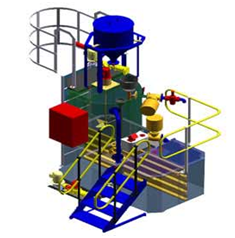

JUNYUE offers the chemical preparation and doing system for the water-treatment purpose. The system is designed modularly and therefore pre-mounted when delivered, which frees the client from cost-heavy installations, and allows for immediately out-of-box uses. The system is automatically self-managed, and it is capable of self-adjusting its operations proportionally to the measurements received from the sensors, and will alarm when any disruption, such as low intake volume, occurs. JUNYUE chemical preparation and dosing system has the following advantages:

- Compact design and standardized specifications

- The installation is low-effort and flexible

- Only needs to be connected with the hydraulic and electrical supply lines to operate

- Versatile and practical process integration

- Suitable for any solution concentration

Applications

The JUNYUE chemical preparation and dosing system can produce solution up to 2600L per 60 mins chemical curing time; the vessel material can be stainless steel 304, stainless steel 316L, PP, PVC or HDPE, whilst the dry chemical feeder and mixer can be made of stainless steel 304 or stainless steel 316L. As the system is produced to match the market standard, it can co-operate with vast number of optional equipments such as vacuum feed conveyor, on-line dilute system or static mixer. Our chemical preparation and dosing systems are typically served in the following uses:

- Metering acids and base to adjust pH value

- Metering biocides and scale-inhibitor in Cooling Water System

- Metering precipitants in effluent water treatment

- Metering cleaning agents (CIP, CEB, etc)