Equipment Description

The TC series ceramic vacuum filter press manufactured by Nuclear Industry Yantai Tongxing is a newly developed filtration equipment with advantages of efficient and energy-saving. The ceramic vacuum filter press integrates the technology of micro-pore ceramic and ultrasonic and it achieves solid-liquid separation through vacuum suction and capillary effect. It has been widely applied in the area of mining, metallurgy, chemical industry and environmental protection. The major components of this equipment includes ceramic filtration plate, main engine, constant pressure gas-water mixed back washing system and control system. The ceramic vacuum filter press has following advantages.

- Highly vacuum, filtration cake of low water content

- Solid content in the filtrate < 50ppm

- Reduce 90% energy-consumption compared to conventional equipment

- Capable of filtration cake cleaning

- High degree of automatic control

- Compact design, small floor space

- Advanced effluent discharge system

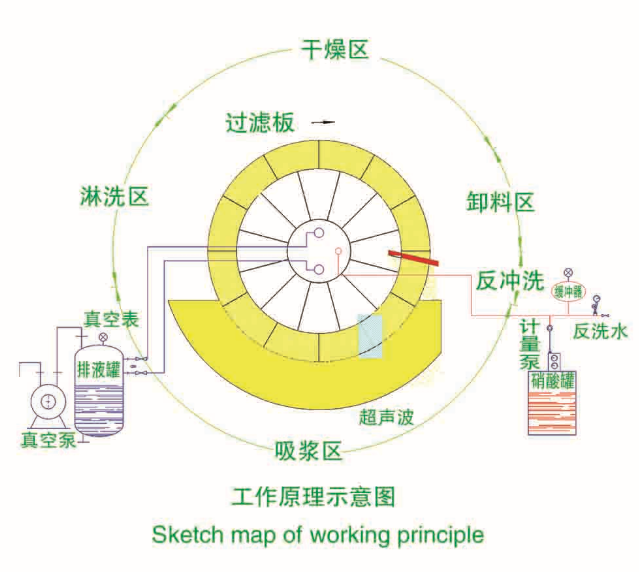

Working Process

- Slime absorbing zone: the ceramic filtration plates immersed in the slime will form a filtration cake under the action of capillary effects and vacuum suction force and the filtrate will pass through the plates to the discharge tank.

- Leaching zone: after the filtration cake rotated out of the slime hopper, it will be washed by spraying.

- Drying zone: continuous dehydration to filtration cake by the action of high vacuum force.

- Discharging zone: scraper will automatically discharge materials once entering the vacuum-free area.

- Back washing: industrial process water or filtrate will pass through ceramic filtration plate to wash the blocked micro-pore from inside to outside. After one period of using the plates, the plates will be washed by low concentration acid, together with ultrasonic technology, to maintain the efficiency of the plates.